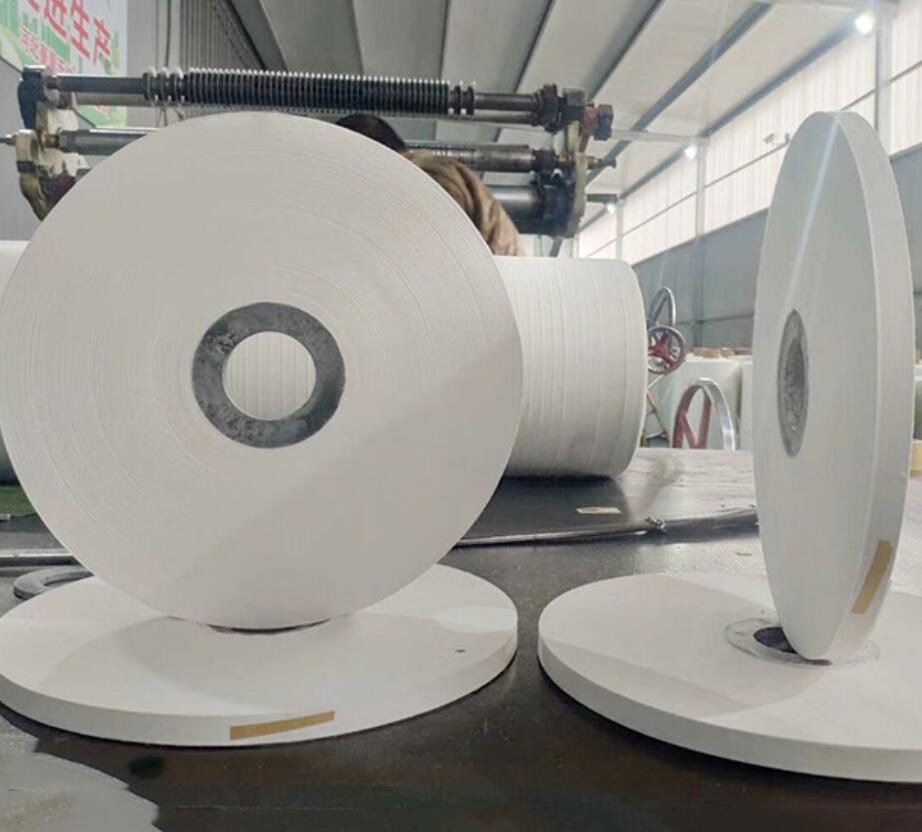

Name:Cable non woven fabrics/Plain Non Woven Fabric

Application:

Cable nonwovens are widely used in various wires and cables requiring moisture and water resistance:

High-voltage and ultra-high-voltage power cables

Submarine cables (which require extremely high water resistance)

Optical cables (especially GYTA and GYTS cables, used for core filling and armor lining)

Railway cables (such as subways and high-speed trains)

Mining cables

Other specialty cables

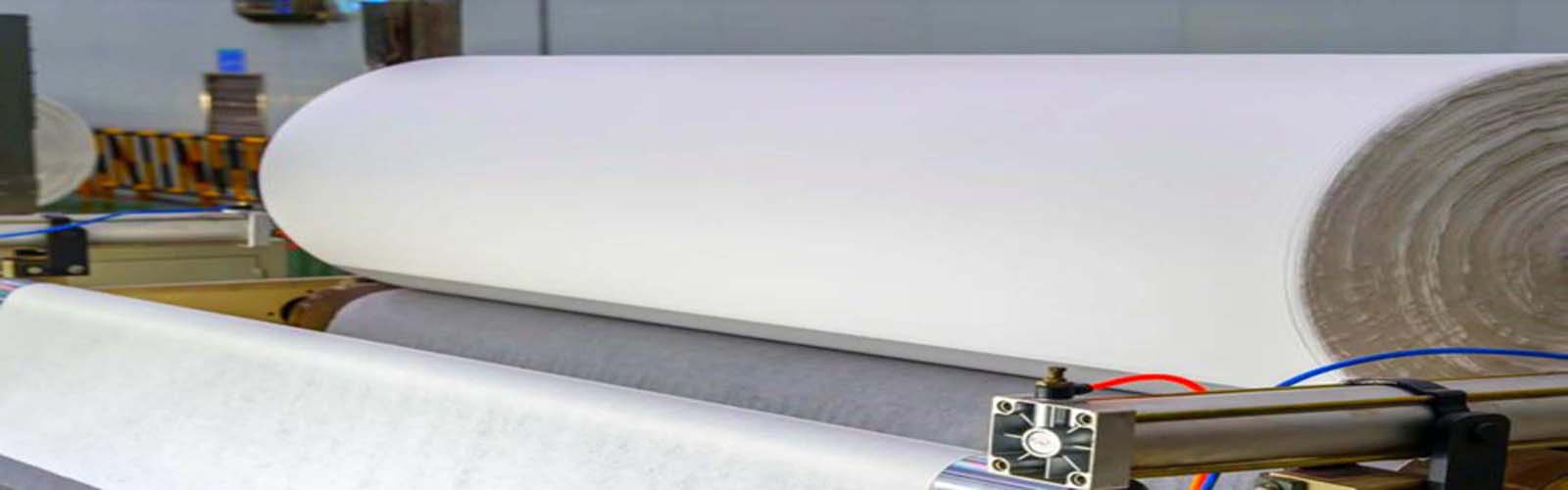

Description:Cable nonwoven fabric, commonly known as cable waterblocking tape or cable nonwoven fabric, is a key non-metallic material used in the power cable and optical cable industries. It's not the common "nonwoven fabric" used in shopping bags, but a specially designed and processed industrial textile with the primary functions of longitudinal water blocking and structural filling.

Application:

Cable nonwovens are widely used in various wires and cables requiring moisture and water resistance:

High-voltage and ultra-high-voltage power cables

Submarine cables (which require extremely high water resistance)

Optical cables (especially GYTA and GYTS cables, used for core filling and armor lining)

Railway cables (such as subways and high-speed trains)

Mining cables

Other specialty cables

Main Functions and Effects

Core Function: Longitudinal Water Blocking

When the cable sheath (outer layer) is accidentally damaged, water can penetrate longitudinally through gaps within the cable, potentially causing long-distance line damage.

Cable non-woven fabrics are typically made from superabsorbent fibers (such as polyester or viscose fibers mixed with superabsorbent resin (SAP)). Upon contact with water, the SAP within the fibers rapidly expands into a gel-like structure, plugging the gaps within the cable and forming an effective water barrier. This limits water penetration to the vicinity of the damage point, protecting the conductors and insulation within the cable core.

Structural Filling and Buffering

During the cabling process, irregular gaps form between the strands of insulated wire. Filling these gaps can maintain a rounded cable cross-section.

Non-woven tapes, with their thickness and elasticity, can be used as filler strips, providing effective cushioning, preventing abrasion between the wires during bending and compression, and enhancing the cable's mechanical strength and stability.

Isolation and Thermal Insulation

It can serve as an isolation layer between different components, such as conductors and metal shields, to prevent electrochemical corrosion or physical damage caused by long-term contact and vibration.

Its porous fiber structure also provides certain thermal and electrical insulation properties.

Enhancing Wrapping Stability

During the armoring process (metal tape or steel wire protective layer), a non-woven fabric buffer layer is often wrapped around the cable core first. This layer smoothes the cable surface and acts as a cushion to prevent the armor layer from damaging the internal insulation.

can not be empty

The E-mail format is not correct

can not be empty